About UHMWPE Fabric

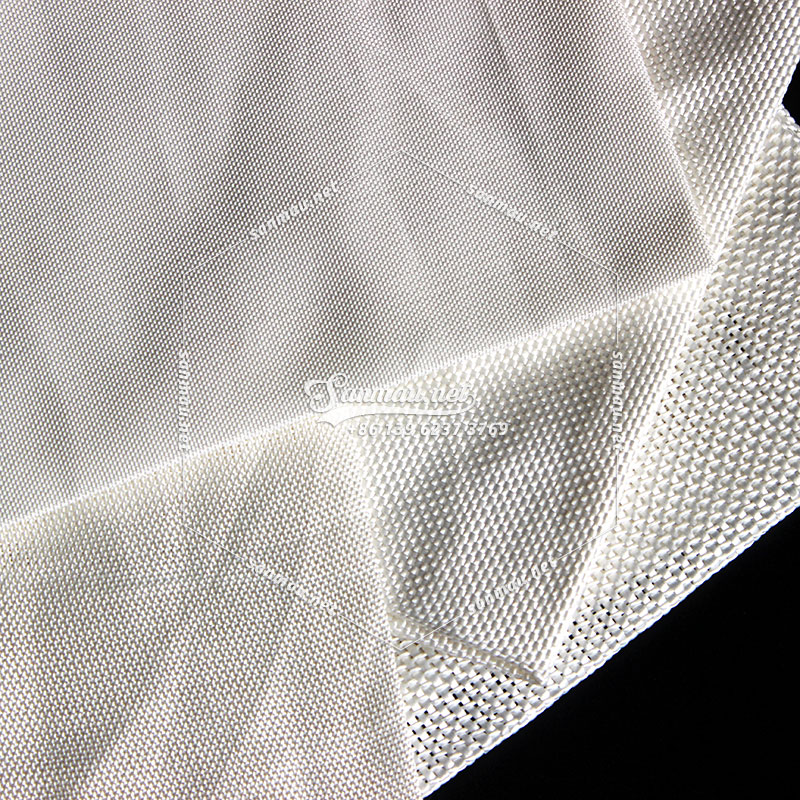

In gereral, UHMWPE Fabrics included woven, knitted and non-woven fabrics, which were made of UHMWPE fibers with different producing techniques. All of them have the excellent features of high tensile strength, abrasion resistance and cut risistance, much better than ordinary polyester fabrics, nylon fabrics and the others.

About UHMWPE | Dyneema® | Spectra® Fibers

Key Advantage of UHMWPE:

Ultra-high tensile strength,

Excellent strength to weight ratio, which means strong and light

High abrasion resistance, good cut resistance

Low specific gravity, float on water

UV stable and long-term serve in seawater

Chemically inert except for strong oxidizing acids

Resistant to fatigue & internal friction

ONLY DISADVANTAGE: CAN NOT BEAR HIGH TEMPERATURE, NOT MORE THAN 120C/248F TEMPORARILY. RECOMMENDED LONG-TERM WORKING TEMPERATURE IS BELOW 80C/176F.

Most Used Woven UHMWPE Fabric: 180/240/300/400gsm

The others might be some in stock or need make-to-order: 66/85/120/130gsm, please inquiry for sure

Woven and Knitted UHMWPE Fabrics are in Adequate Supplies

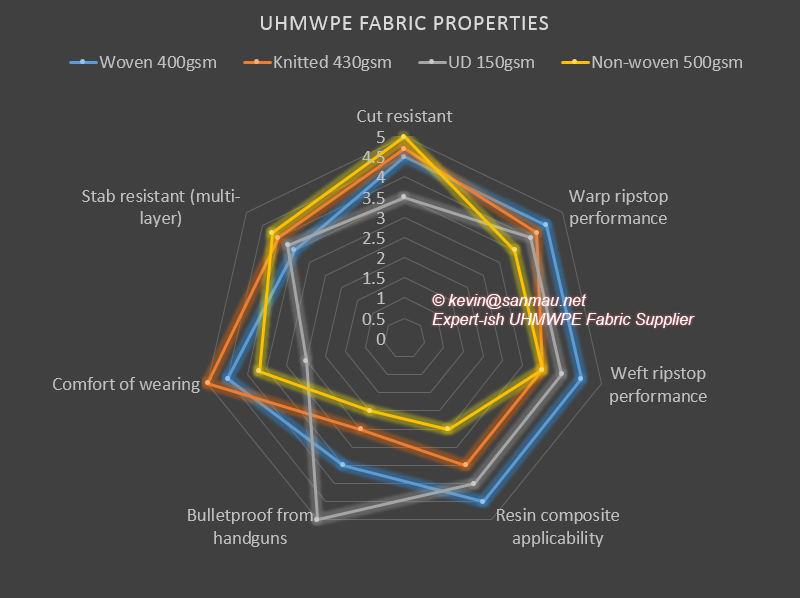

Confused with the fabrics that made of UHMWPE fibers?

A chart will impress you a general idea

Applications of UHMWPE Fabric

Bulletproof Uniforms

Composite with Ceramic Plate for Bulletproof

Cut Resistant Gloves, Uniforms, Sleeves

Terms of Cooperation

For more details, PLEASE DO NOT HESITATE to write me an e-mail, or just dial the number directly.

|

|||||||||||||||