Define: Kevlar® & Nomex® Fiber

These two brands are belong to DuPontTM. They are most used ARAMID material, which Kevlar® is para-aramid and always has a natural color of yellow, on the other hand, Nomex® is meta-aramid and has a natural color of white.

Kevlar® has successfully emerged out as one of the ultra high-performance fiber since it’s been first introduced by Stephanie Kwolek on 1971, and was registered by DuPont as a famous para-aramid material commercial brand. This magic fiber has various amazing features: long-term working in high-temperature environment, high tensile load, low elongation.

Advanced Properties of Kevlar® | Para-Aramid fiber

High strength to weight ratio

Low elongation to break

Low thermal shrinkage

Good heat & flame resistance

Self-extinguishing flame retardant properties

Good chemical resistance

Excellent bulletproof/ballistic properties

High cut resistance (not so easy to cut off than normal fibers)

UV resistance good (ONLY on black and other non-natural color fiber)

UV resistance poor (natural, and please notice this is the MAIN WEAKNESS of aramid fiber)

Common Types & Deniers

T-29: Standard Modulus

T-49: High Modulus

AP: 15% higher tenacity than T-29

KM2: Optimized ballistic resistance

Deniers: 200, 380, 400, 750, 800, 1000, 1420, 2160, 2250, 2840, 3000, 7100

Advanced Properties of Nomex® | Meta-Aramid fiber

Lower elongation to break

the 4th level of dye colorfastness, dyeable

Low thermal shrinkage

Excellent heat & flame resistance

Self-extinguishing flame retardant properties

Soft-hand yields good textile properties

High chemical resistance

Common Types & Deniers

T-430: Filament Yarn

Deniers: 200, 1200, 1600, 2400

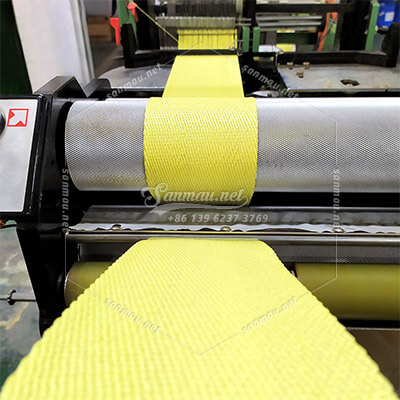

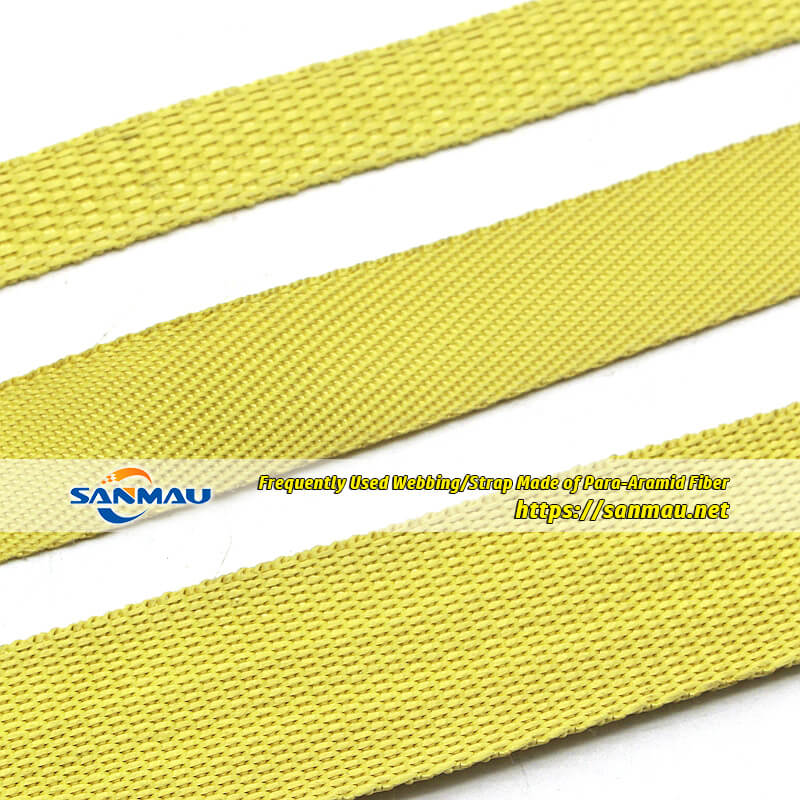

Para-Aramid Thread Woven Webbing

The thicker the harder to produce, upper limit is 5mm

80mm in Width, 2mm in Thickness

100x4mm Heavy Duty Aramid Webbing in Production

About Kevlar® | Aramid Webbing

Sanmau produced high-performance Webbing is a critical component in protective flame-resistant clothing, harnesses, and helmets required for aerospace, military, first responders, tactical and industrial safety equipment and Personal Protection Equipments (PPE). The protective area includes physical, electrical, heat, chemicals, biohazards, and airborne particulate matters.

Can be customized as your demand

The Width of 5~150mm, the thickness of 0.1~5mm, several woven patterns for choice

Comparision of Materials

For complicated working conditions, ordinary materials are more and more replaced by aramid, UHMWPE, PBO fibers. With these advanced fibers, we managed to develop a series of textile which includes sewing thread, string, rope, straps, webbing, and fabric. Here’s the table of specifications of various materials:

| Material | Density (g/cm³) |

Tensile strength (GPa) |

Specific strength | Elastic modulus (GPa) |

Specific modulus |

|---|---|---|---|---|---|

| Steel re-bar | 7.85 | 0.5 | 0.0667 | 210 | 26.7 |

| A-glass | 2.46 | 2.1 | 1.35 | 69 | 28.0 |

| C-glass | 2.46 | 2.5 | 1.35 | 69 | 28.0 |

| E-glass | 2.60 | 2.5 | 1.33 | 76 | 29.2 |

| S-2 glass | 2.49 | 4.83 | 1.94 | 97 | 39.0 |

| Silicon | 2.16 | 0.206–0.412 | 0.0954–0.191 | ||

| Quartz | 2.2 | 0.3438 | 0.156 | ||

| Carbon fiber (large) | 1.74 | 3.62 | 2.08 | 228 | 131 |

| Carbon fiber (medium) | 1.80 | 5.10 | 2.83 | 241 | 134 |

| Carbon fiber (small) | 1.80 | 6.21 | 3.45 | 297 | 165 |

| Kevlar K-29 | 1.44 | 3.62 | 2.51 | 41.4 | 28.8 |

| Kevlar K-149 | 1.47 | 3.48 | 2.37 | ||

| Polypropylene | 0.91 | 0.27-0.65 | 0.297–0.714 | 38 | 41.7 |

| Polyacrylonitrile | 1.18 | 0.50-0.91 | 0.424–0.771 | 75 | 63.6 |

| Basalt fiber | 2.65 | 2.9–3.1 | 1.57–1.81 | 85–87 | 32–33 |

Applications of Kevlar® | Aramid Webbing

Fire Fighting Equipments

Structure Reinfoced

Military Equipments

Terms of Cooperation

For more details, PLEASE DO NOT HESITATE to write me an e-mail, or just dial the number directly.

|

|||||||||||||||

Q&A about Kevlar Webbing

PREFACE: Dyneema is a brand name of UHMWPE which belongs to DSM, I will describle UHMWPE instead of Dyneema. And the same of Kevlar to Aramid.

What’s the difference between Kevlar webbing & Dyneema Webbing?

They all have the features of ultra strong tensile strength, although UHMWPE webbing is better than Aramid webbing. But UHMWPE has the major disadvantage that compared with aramid is, it cannot bear a high temperature more than 120C. So if your webbing components shall work in a harsh and heated environment, then you should choose aramid webbing. Otherwise, you can choose UHMWPE webbing which is stronger and cheaper.

Yes, UHMWPE is cheaper than aramid in material, about half the price.

Is Sanmau bulk supply available?

Off course, we are the rare manufacturer that has the full braiding and weaving lines of ultra performance fibers.

How much is Kevlar webbing by the foot/yard?

It depends on the width and the thickness of the webbing. For there are various types, please let me know the specification which you demand, then I can offer accurate quotes for you.

What’s the most used type of Kevlar webbing?

2inches|50mm, 1.75inches|45mm and 1.5inches|38mm in width. But the thickness also has various types. It’s really hard to produce every type of webbing as there are so many. So we might have the adjacent produced type for sample, but if you have the specific model required, mostly we need to make them after your order.

Is sanmau a manufacturer of webbing?

Absolutely yes, and we have a full manufacturing system of textiles made of Ultra Performance Fibers. Not only can provide special sewing threads, strings, rope, straps, webbing, and fabric, also can make them with para-aramid | Kevlar, meta-aramid | Nomex, UHMWPE | Dyneema | Spectra, PBO, etc.

Is Kevlar webbing good for hammock tree straps?

No exactly. Two reasons, it’s more expensive than UHMWPE webbing which is better for a hammock, and aramid has the feature that cannot have the exposure under the sunlight, especially the UV light. UV can cause performance reduction rapidly. And the fact is, hammock never closed to a fire, which is the aramid usually faced to. So it’s the wrong way to use aramid webbing as hammock straps.

How much the high temperature is that Kevlar webbing can stand?

For different woven techniques, the thicker the products are, the better they can bear the heat. Like 2mm in the thickness of Kevlar webbing is better than 0.58mm in the thickness of Kevlar fabric(420gsm) in heat bearing. Mostly the safe working temperature of Kevlar/Para-aramid products are below 260C|500F, temporarily work below 320C|600F. The best way to find out is to have the sample to test, please send me an inquiry e-mail.